How we make it

Processes & technology

Owing to our wide ranging expertise, from our traditional model making processes to the latest technologies, we are able to tackle almost any project in house.

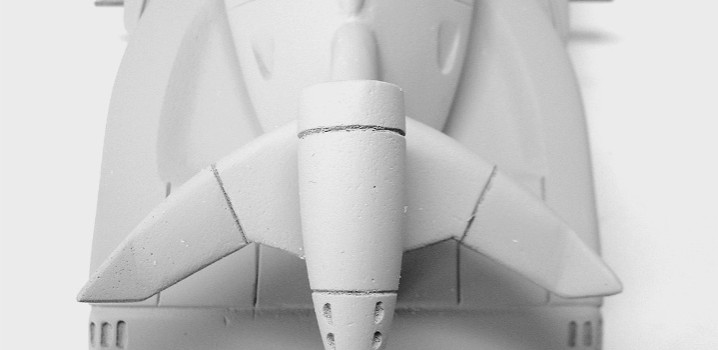

Rapid prototyping

Including CAD, CNC, SLA.

Stereolithography (SLA) sometimes referred to as 3D Printing, is a technique or process for creating three-dimensional objects, in which a computer-controlled laser is used to build up the required structure, layer by layer, from a liquid polymer that hardens on contact with laser light.

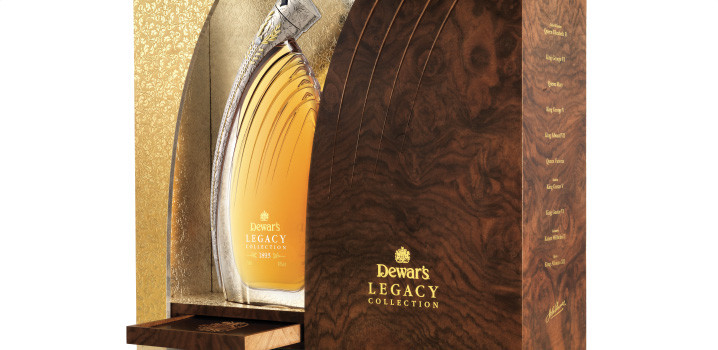

Traditional

model making

Utilising manual machinery hand-tools and traditional materials.

At Atom, we invest in our people and nurture talent. Our skilled multidisciplinary group of expert craftsmen and makers pride themselves on quality of finish and presentation. Whether a prototype calls for a bespoke airbrush finish, delicate dry transfer decals or intricate cabinetry you can trust our experts to deliver.

Sculpting

We can sculpt almost anything. We once sculpted a 20ft pineapple with a chainsaw.

Working from any visual reference, we can produce any form where CAD data may not exist. Our skilled artists are able to capture intricate organic, non parametric form.

Vacuum casting

Simulation of injection mould and blow with fast turnaround

Vacuum forming

Rapid tooling for vacuum forming enables multiple production and fast product iteration and incorporation

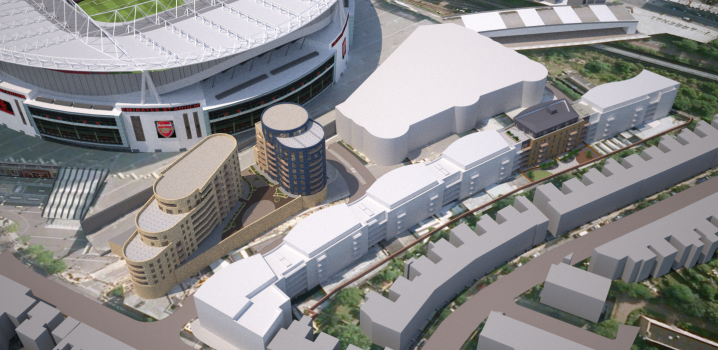

Visualization

3D visualization, including montage and scenes, walk through and fly-by

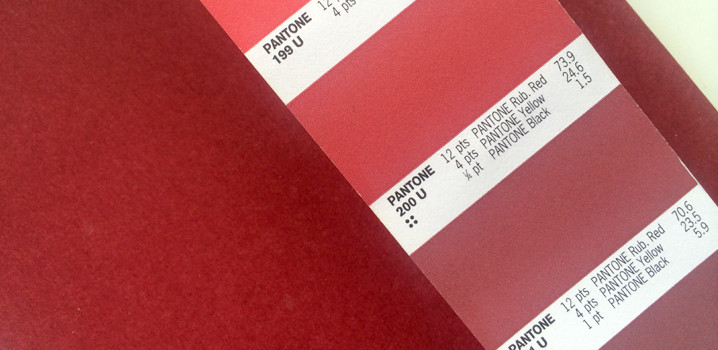

Accurate

colour matching

Accurate colour matching and specialist finishes

High level finishing

We provide specialist and unique appearances

In house graphic

creation (decals)

Full colour transfers, embossing, and digital print